I-anti-theft door embossing hydraulic press

Icala Lenkampani

Isicelo

Lo mshini ulungele ngokuyinhloko ukufaka iminyango yensimbi.Imishini inokuqina okuhle kwesistimu nokunemba okuphezulu, impilo ephezulu nokuthembeka okuphezulu.Inqubo yokuqopha yezingxenye zensimbi yeshidi ihlangabezana namashifu ama-3/ukukhiqizwa kosuku.

Amapharamitha womshini

| Igama | Iyunithi | Inani | Inani | Inani | Inani | |

| Imodeli |

| I-Yz91-4000T | I-Yz91-3600T | I-Yz91-2500T | I-Yz91-1500T | |

| Amandla e-cylinder amakhulu | KN | 40000 | 36000 | 25000 | 15000 | |

| Ukukhanya kwasemini | mm | 500 | 500 | 500 | 500 | |

| Main cylinder Stroke | mm | 400 | 400 | 400 | 400 | |

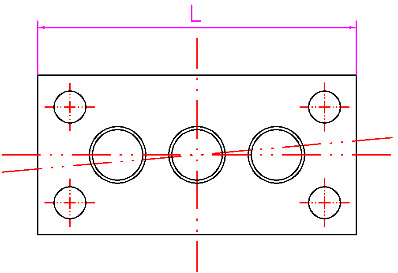

| Isilinda Qty. | / | 6 | 6 | 6 | 6 | |

| Usayizi wethebula

| LR | mm | 1600 | 1600 | 1400 | 1400 |

| FB | mm | 2600 | 2600 | 2400 | 2400 | |

| Isivinini sesilayidi | Phansi | mm/s | 80-120 | 80-120 | 80-120 | 80-120 |

| Buyela | mm/s | 100 | 100 | 100 | 100 | |

| Iyasebenza | mm/s | 10-15 | 10-15 | 10-15 | 10-15 | |

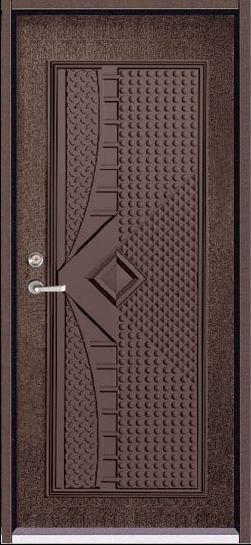

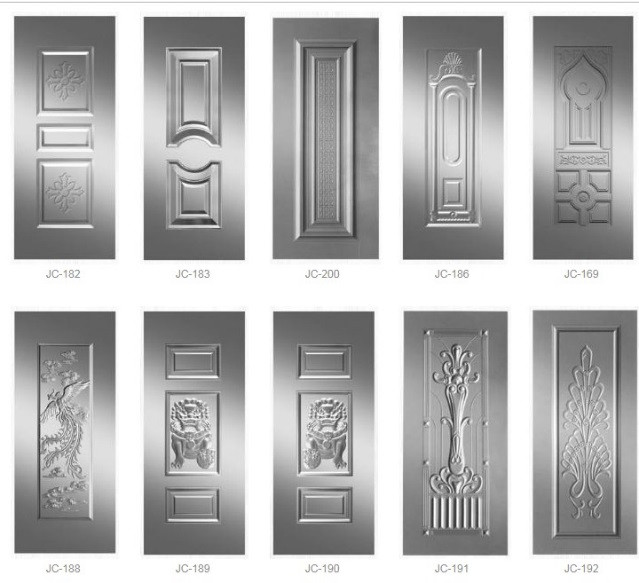

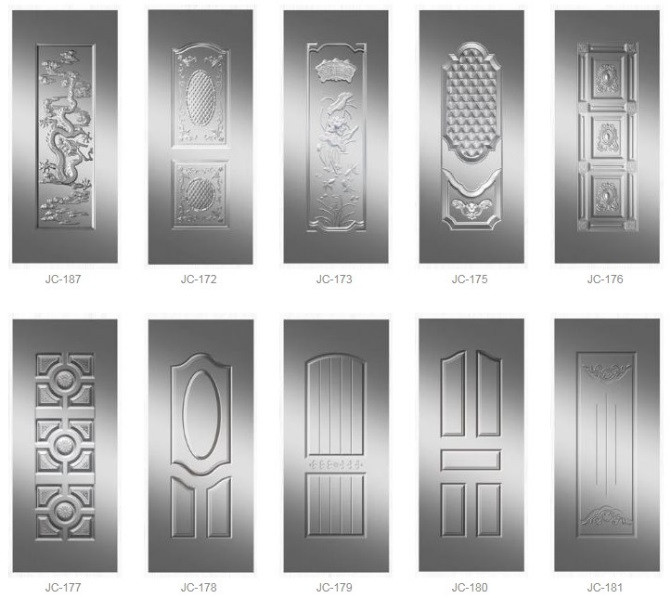

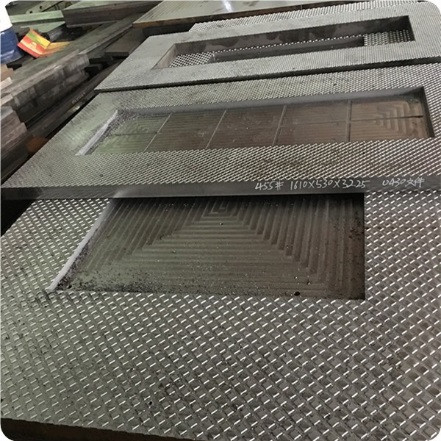

Isikhunta somnyango namaphethini

Singahlinzeka ngamaphethini ahlukene ukuze amakhasimende akhethe, singanikeza isikhunta.Isikhunta sizohlolwa efektri yethu.

Isikhunta siqukethe isethi engu-1 yefreyimu yesikhunta kanye namasethi amaningi e-mold cores, ikhasimende lingenza iphethini ehlukile, futhi lidinga kuphela ukuthenga isethi engu-1 yohlaka lwesikhunta.

Idivayisi yokuphepha

I-Photo-Electrical Safety Guard Front nangemuva

Ukukhiya isilayidi ku-TDC

I-Two Hand Operation Stand

Hydraulic Support Insurance Circuit

Ukuvikela Ukulayisha Okungaphezulu: Ivaluzi Yokuphepha

I-alamu Yezinga Loketshezi: Izinga likawoyela

Isexwayiso sokushisa kwamafutha

Ingxenye ngayinye kagesi inokuvikelwa kokugcwala ngokweqile

Amabhulokhi okuphepha

Amantongomane okukhiya ahlinzekelwe izingxenye ezihambayo

Zonke izenzo zokucindezela zinomsebenzi we-interlock wokuphepha, isb. ithebula lokusebenzela eligudlukayo ngeke lisebenze ngaphandle uma umcamelo ubuyela endaweni yokuqala.Isilayidi asikwazi ukucindezela uma ithebula lokusebenza eligudlukayo licindezela.Uma ukusebenza kokungqubuzana kwenzeka, i-alamu iyavela kusikrini esithintwayo futhi ibonise ukuthi yini ukungqubuzana.

Uhlelo Lokulawula Ugesi

1. Uhlelo lukagesi luqukethe isifunda samandla kanye nesifunda sokulawula.Isekhethi yamandla yi-380V, 50HZ, enesibopho sokuqala, ukumisa nokuvikela injini yepompo likawoyela.Uhlelo lwesekethe yokulawula lusebenzisa isilawuli esihlelekayo se-PLC esihlanganiswe nokulawula okuyinhloko kwesikrini sokuthinta ukuze kubonakale imijikelezo yenqubo ehlukahlukene yethuluzi lomshini.

2. Izingxenye eziyinhloko zokulawula ukusabalalisa amandla zifakwe kwikhabhinethi yokulawula enkulu, futhi ikhabhinethi yokulawula enkulu ibekwe phansi ngakwesokudla kwefuselage;izingxenye zokwenziwa kwemishini zixhunywe izintambo ezithambile, izitolo ezinkulu zekhabhinethi zivamile, futhi imigqa yokulawula ixhunywe ngama-plug-ins wendiza ukuze kuhlakazwe kalula Ngokulungiswa kabusha.

3. Umsebenzi oyinhloko wengxenye yokulawula uthathwa yisilawuli se-"PLC" esihlelekayo esihlelekayo.Ngokuya ngezidingo zenqubo, imiyalo ekhishwe yizingxenye zokulawula eziyinhloko (amaswishi okukhetha, izinkinobho, njll.), ngokusekelwe kumasiginali akalwa ngezinto zokuthola njengezinzwa zokuthutha, ukushintsha kohambo, izinzwa zokucindezela, njll., inqubo. amanani okushintsha kanye ne-analog omshini kanye nokushayela I-valve yokushayela engu-hydraulic nezinye izisetshenziswa ziyakubona ukulawulwa kokucindezela nokugudluzwa kwe-hydraulic actuator-cylinder, bese iqedela inqubo yokukhiqiza umshini.

Ukushaywa kwesilayidi kulawulwa inzwa yokususa ngokuphelele.Inzwa yokususa ihlelwe engxenyeni engenhla yangaphakathi yekholomu.I-stroke kanye nephoyinti lokuguqulwa kwesikhundla lingasethwa ngokuqondile futhi liboniswe esikrinini sokuthinta.Ngaphezu kwalokho, kukhona ukushintsha komkhawulo ophezulu naphansi wokuvikela kabili ezimeni ezingalindelekile.

4. Iphaneli yokulawula ukusebenza okumaphakathi kwemishini ihlelwa ekhabetheni eliyinhloko lokulawula, futhi isikrini sokubonisa semboni yephaneli yokuthinta, ukukhanya kwenkomba yesimo sokusebenza nezinkinobho zokusebenza ezidingekayo kanye nokushintsha kokukhetha kuhlelwa kuphaneli.Isistimu kagesi iqukethe isekethe yamandla. kanye nesifunda sokulawula.Isekhethi yamandla yi-380V, 50HZ, enesibopho sokuqala, ukumisa nokuvikela injini yepompo likawoyela.Uhlelo lwesekethe yokulawula lusebenzisa isilawuli esihlelekayo se-PLC esihlanganiswe nokulawula okuyinhloko kwesikrini sokuthinta ukuze kubonakale imijikelezo yenqubo ehlukahlukene yethuluzi lomshini.

Izingxenye eziyinhloko zokulawula ukusabalalisa amandla zifakwe ekhabhinethi yokulawula enkulu, futhi ikhabhinethi yokulawula enkulu ibekwe phansi ngakwesokudla kwefuselage;izingxenye zokwenziwa kwemishini zixhunywe izintambo ezithambile, izitolo ezinkulu zekhabhinethi zivamile, futhi imigqa yokulawula ixhunywe ngama-plug-ins wendiza ukuze kuhlakazwe kalula Ngokulungiswa kabusha.

5. Umsebenzi oyinhloko wengxenye yokulawula uthathwa yisilawuli se-"PLC" esihlelekayo esihlelekayo.Ngokuya ngezidingo zenqubo, imiyalo ekhishwe yizingxenye zokulawula eziyinhloko (amaswishi okukhetha, izinkinobho, njll.), ngokusekelwe kumasiginali akalwa ngezinto zokuthola njengezinzwa zokuthutha, ukushintsha kohambo, izinzwa zokucindezela, njll., inqubo. amanani okushintsha kanye ne-analog omshini kanye nokushayela I-valve yokushayela engu-hydraulic nezinye izisetshenziswa ziyakubona ukulawulwa kokucindezela nokugudluzwa kwe-hydraulic actuator-cylinder, bese iqedela inqubo yokukhiqiza umshini.

Ukushaywa kwesilayidi kulawulwa inzwa yokususa ngokuphelele.Inzwa yokususa ihlelwe engxenyeni engenhla yangaphakathi yekholomu.I-stroke kanye nephoyinti lokuguqulwa kwesikhundla lingasethwa ngokuqondile futhi liboniswe esikrinini sokuthinta.Ngaphezu kwalokho, kukhona ukushintsha komkhawulo ophezulu naphansi wokuvikela kabili ezimeni ezingalindelekile.

6. Iphaneli yokulawula ukusebenza emaphakathi yemishini ihlelwa kukhabhinethi yokulawula enkulu, futhi isikrini sokubonisa semboni yephaneli yokuthinta, ukukhanya kwenkomba yesimo sokusebenza nezinkinobho zokusebenza ezidingekayo kanye nokushintsha kokukhetha kuhlelwa kuphaneli.

IHydraulic System

Isici:

1. Ithangi likawoyela limiselwe uhlelo lokupholisa oluphoqelekile (idivayisi yokupholisa amanzi yohlobo lwezimboni, ukupholisa ngamanzi ajikelezayo, izinga lokushisa likawoyela≤55℃,qiniseka ukuthi umshini ungacindezela kancane emahoreni angama-24.

2. Uhlelo lwe-hydraulic lusebenzisa uhlelo lokulawula i-cartridge valve edidiyelwe ngesivinini sokuphendula esisheshayo kanye nokusebenza kahle kokudlulisa.

3. I-tank yamafutha ifakwe isihlungi somoya ukuze uxhumane nangaphandle ukuze kuqinisekiswe ukuthi uwoyela we-hydraulic awungcolisiwe.

4. Ukuxhumana phakathi kwe-valve yokugcwalisa kanye ne-fuel tank isebenzisa ukuhlanganiswa okuguquguqukayo ukuvimbela ukudlidliza ukuthi kungadluliswa ku-tank fuel futhi ukuxazulula ngokuphelele inkinga yokuvuza kwamafutha.

Ukunyakaza Kwezobuchwepheshe

1.Umshini wokucindezela ungasebenza ngezindlela ezi-4: ukulungiswa (i-Inching), i-manual, i-semi-automatic kanye ne-othomathikhi egcwele, imodi yokusebenza nayo ingahlukaniswa ngezindlela ezi-2: ukwakheka kwebanga eliqhubekayo kanye nokwakhiwa kwengcindezi engaguquki.

2. Imodi yebanga eliqhubekayo:Lapho izindawo zamanje zesilayidi ne-cushion zifinyelela endaweni esethiwe, umsebenzi wamanje uyamiswa.Inani lebanga elingaguquki lamaslayidi lingaphakathi kwebanga le-stroke egcwele yesilayidi.

3. Imodi yokucindezela njalo:Lapho izingcindezi zamanje zesilayidi ne-cushion zifinyelela ukucindezela osethiwe, umsebenzi wamanje uyamiswa.

4. Ukulungisa(i-inches):Sebenzisa izinkinobho zokusebenza ezihambisanayo ukuze uqedele izenzo ezihambisanayo.Ukucindezela inkinobho isikhathi esisodwa kwenza umshini wokucindezela uqedele u-intshi wesikhathi esisodwa.Umshini wokucindezela uyamiswa lapho inkinobho ikhishwa.Le modi isetshenziswa kakhulu ukulungisa umshini wokucindezela bese ufaka esikhundleni sokufa.

5. Imanuwali:Cindezela inkinobho ngayinye yomsebenzi ukuze uqedele isenzo esifanayo, ukucindezela ngakunye kuqeda isenzo esi-1 ngesikhathi.

6. I-Semi-automatic:Inkinobho yokucindezela ezandla ezimbili ukuqedela umjikelezo owodwa: Uma inkinobho enezandla ezimbili icindezelwa, umshini wokucindezela uqedela isethi yezenzo zenqubo (Inqubo yomjikelezo kufanele isethwe kusengaphambili)

Ukucaciswa Kwe-Welding Yomzimba Oyinhloko

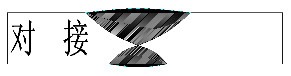

| Isitayela | I-TLCH | KB | Isidingo |

|

| I-A-side H=T2/3 Uhlangothi lwe-B H=T1/3 C≥4 L≤3 | I-A-side 60 ° B-side 35° 1/4≤K≤T | izinhlangothi ezimbili i-tack-weld kuqala bese i-back-weld, i-cosmetic-weld yokugcina |

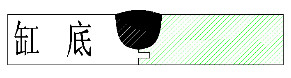

| Isilinda phansi

| Ngokusho kwe-Drawing | Ngokusho kwe-Drawing | izinhlangothi ezimbili i-tack-weld kuqala bese i-back-weld, ngemuva kwe-cosmetic-weld igcina ukushisa |

| I-A-side H=T/2 Uhlangothi B H=T/3 C≥4 L≤3 | I-A-side 60 ° B-side 35° 1/4≤K≤10 | izinhlangothi ezimbili i-tack-weld kuqala bese i-back-weld, i-cosmetic-weld yokugcina |

| I-V-shape groove H=T/3 C≥4 L≤3 | 40o≤B≤60o 1/4≤K≤8 | izinhlangothi ezimbili i-tack-weld kuqala bese i-back-weld, i-cosmetic-weld yokugcina |

| I-Double-V groove H=T/3 C≥4 L≤3 | 40o≤B≤60o 1/4≤K≤8 | izinhlangothi ezimbili i-tack-weld kuqala bese i-back-weld, i-cosmetic-weld yokugcina |

| I-V-shape Groove H=T/3 C≥4 L≤3 | 40o≤B≤60o 1/4≤K≤8 | Ukucutshungulwa komumo we-T njengenhla, ukushisela ipuleti elehlelayo ngemva kokuqedwa komumo we-T |

|

| I-V-shape groove H=T2/3 C≥4 L≤3 | B≤60o 1/4≤K≤10 | i-tack-weld kuqala bese i-back-weld, i-cosmetic-weld yokugcina |

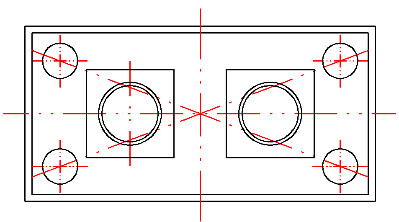

Ithebula Lokubekezelela Ukwakheka Komzimba

| Isakhiwo | Into | Ukubekezelelana |

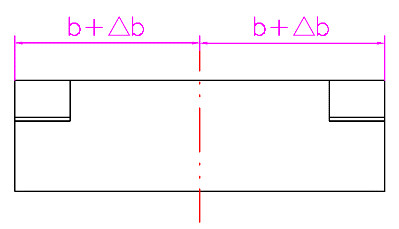

| I-Symmetry Yezinto Zangaphandle Zesakhiwo Se-Fuselage(Ukubekezelela isikhala△ b) | b≤1000 △b≤1.5 1000 b>2000△b≤3.0 |

| Isakhiwo se-Fuselage esingunxande(ukubekezelelana kwe-diagonal L△ L) | L≤2000 △L≤3.0 2000 L>4000△L≤5.0 |

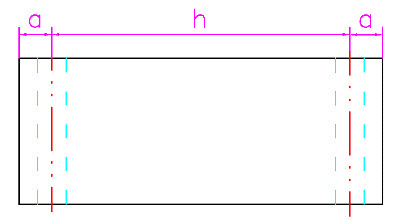

| Ukufana phakathi kwePhezulu neGround of Column Structure t(Ukuthambekela Kufaka Izingcwecwe Ezingaphezulu Nasezansi) | h≤4000 t≤2.0 4000 h>8000 t≤5.0 |

| Ukungahambi kahle kwamabhodi aphezulu naphansi wesakhiwo se-fuselage | L≤2000 t≤2.0 L>2000 t≤3.0 |

Ukubekezelela I-Angle Welding

| Ibanga | Usayizi Womkhawulo Omfushane mm | |||

| ≤315 | >315 ~ 1m | >1 ~ 2m | >2m | |

| A | ≤1.5 | ≤2.0 | ≤2.5 | ≤3.0 |

| B | ≤2.5 | ≤3.0 | ≤3.5 | ≤4.0 |

| A | ±20′ | ±15′ | ±10′ | _ |

| B | ±1° | ±45′ | ±30′ | _ |

Ukubekezelela Ukuma Kwe-Welding Nesikhundla

| Ibanga | Usayizi Oyisisekelo mm | |||||

| ≤315 | >315~1 | >1 ~ 2m | >2 ~ 4m | >4-8m | >8m | |

| A | 1.0 | 1.5 | 2.0 | 3.0 | 4.0 | 5.0 |

| B | 2.0 | 3.0 | 4.0 | 6.0 | 8.0 | 10.0 |

| C | 3.0 | 5.0 | 9.0 | 11.0 | 16.0 | 20.0 |

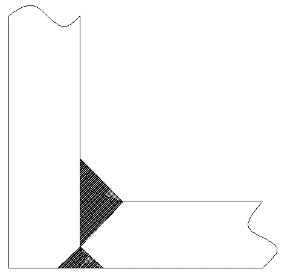

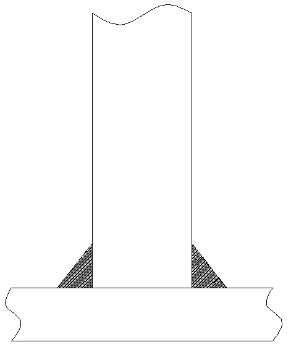

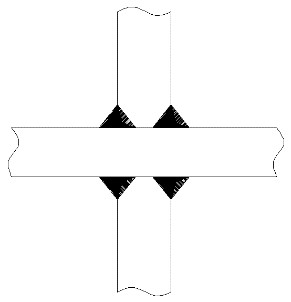

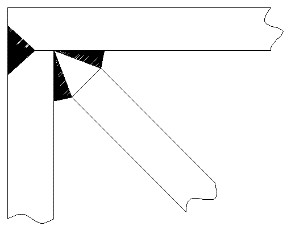

inhlanganisela yezinqe

inhlanganisela yezinqe

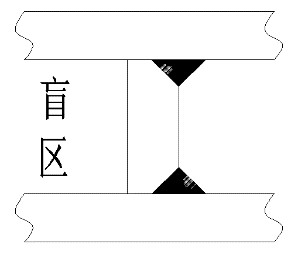

I-BlindZone

I-BlindZone